Guide to the Parts of a Hydraulic Press Brake

Ever wonder how a piece of metal is transformed into an intricate shape? The answer is the hydraulic press brake.

The parts of a hydraulic press brake work together to deliver power and precision in manufacturing. Understanding how each component functions in your production is useful for operators and essential in keeping production efficient and avoiding costly downtime.

In other words, getting familiar with the parts makes it easier for operators to pinpoint any malfunctions, helping them become better equipped to diagnose the problem and plan for proper maintenance. Then, production can return to top quality quickly.

Below, we’ll cover the main components of a hydraulic press brake, breaking down the key details to help you achieve smoother production.

Overview of a Hydraulic Press Brake

The components of a hydraulic press brake use power to create accuracy in metal forming. This attention to detail is what sets it apart from a hydraulic press - which is used just for general force application. The hydraulic press brake is used to bend and shape sheet metal into different angles and configurations, making it vital in many industries, like construction and automotive, to name a few.

Press brakes use hydraulic cylinders to create an immense force, without sacrificing precision and accuracy. This force translates into consistent, repeatable motion, allowing operators to make clean bends with a small chance of errors.

Main Components of a Hydraulic Press Brake

In the chart below, you’ll find the main components of the hydraulic press brake, along with their primary functions.

|

Component |

Role |

Key Details |

Trouble Spots |

Upkeep |

|

Frame |

Provides structural support and stability |

Absorbs and distributes the force during the operation process |

Loose components |

Inspect the frame weekly to ensure all major connections remain tight |

|

Cylinders |

Provides force |

Translates power into precision |

Leaks and pressure loss are causing cylinders to drift |

Inspect and replace seals, check valves for wear or debris, and ensure fluid is clean |

|

Hydraulic Power Unit (HPU) |

Creates pressure |

Includes the tank, motor, hoses, pumps, and filters |

Contamination, overheating, leaks, loss of pressure |

Inspect weekly to make sure the unit is free of debris and leaks, all components are connected, and there is enough oil |

|

Pump |

Converts mechanical force and motion into hydraulic fluid power |

Drives hydraulic fluid through the system and generates power |

Low or no pressure |

Check weekly to ensure there is proper there |

|

Valves |

Maintains the hydraulic pressure (via the relief valve) while enabling high-capacity flow |

Protects system from overpressure damage |

Adjusting the relief valve out of the factory setting creates a malfunction in the system, which leads to wear and tear on all components |

Keep the valve in the factory setting, and contact the manufacturer if need be |

|

Ram |

Applies pressure on the forming tool via a beam in the center of the machine |

Slides vertically in the upper part of the machine |

Misalignment, hydraulic imbalance, drifting |

Distribute work evenly on the machine to avoid excessive wear |

|

Gib Guiding |

Guides the ram’s motion |

Ensures even movement throughout the cycle |

Misalignment, issues with gib clearance |

Reset settings to OEM-specified tolerance |

|

Side Housing |

Serves as the main support structures that hold the machine together |

Provide stability during metal forming to prevent damage and ensure safety |

Cracking, deformation, misalignment |

Avoid overloading the machine, which can cause premature wear |

|

Electrical Panel |

The control hub of the brake |

Distributes power, manages automation, and protects the machine and operator |

Power disruption and failing components (like wiring) |

Conduct regular inspections to confirm the panel is free of debris, properly connected, and well ventilated |

Frame

Cylinders of a hydraulic press brake are mounted on the frame. They provide the downward force that moves the ram, which drives the ram to form the metal.

Hydraulic Power Unit (HPU)

Acting as the heart of the hydraulic press brake, the HPU consists of the motor, pump, reservoir, and filters. These generate and maintain pressure. The HPU also supplies the press brake with the fluid power needed for the operation.

Pump

The pump of the hydraulic press brake takes the hydraulic fluid from the reservoir and delivers it to the operating system. This determines the flow rate of the fluid, which has a direct effect on the speed and responsiveness of the press brake.

Valves

Generally speaking, valves regulate and direct the flow of the hydraulic fluid in the press brake. Valves are vital for precise ram operation, as they regulate pressure, flow, and direction of the hydraulic fluid.

Ram

The ram is the upper part of the machine. They are the moving part of the press brake that houses the punch that shapes the metal as desired.

Gib Guiding

As suggested, gibs guide the ram’s vertical movement. This part of the press brake restricts lateral movement. They’re made to fit precisely into a corresponding slot in the frame of the press, which aids in the precision of metal forming.

Side Housings

Side housings are vertical structural frames located on each side of the hydraulic press brake. They provide stability, guidance, and alignment to the entire brake during the bending operation, which puts out a great deal of force, anywhere from 750 to 3,000 tons, depending on the model.

Electrical Panel

The electrical panel of the hydraulic press brake houses all of the electrical components that power, control, and protect the press brake and the operator. It coordinates the signals between the operator controls, hydraulic system, safety devices, and motors.

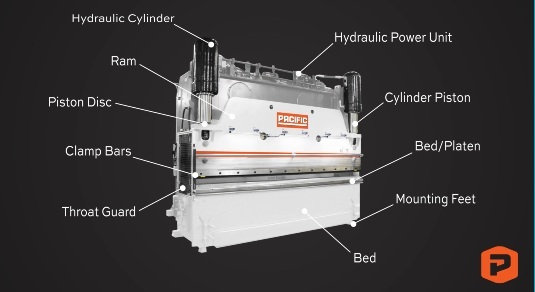

Parts of a Hydraulic Press Brake Unique to Pacific Press

Pacific Press hydraulic press brakes are built with specific components that set them apart from other brands in the industry. These specialty parts are engineered to improve performance and ensure reliable operations. Pacific Press specialty components include:

- Proprietary valves: These are a core component of our hydraulic system. We engineer valves specially for each piece of equipment rather than purchasing them from other manufacturers.

- Pilot valves: These are auxiliary valves that use hydraulic pressure to control the operation of the main valves. Their key functions are to improve safety and control.

- Gibbing: Unique systems that guide the ram’s movement, making sure it moves up and down with precision and parallelism, providing better alignment on the press brake.

- Add-on features: Additional safety features, like light guards, offer additional protection to operators.

Maintenance Tips for Hydraulic Press Brake Longevity

Preventive maintenance is still vital in ensuring the press brake’s longevity and protecting its most critical elements – the frame and the cylinder. These scheduled tasks can minimize or even eliminate many of the issues listed above:

- Inspections of the main components

- Hydraulic fluid checks and filtration

- Proper lubrication of guiding systems

- Replacement intervals for smaller components (seals, valves, and hoses)

Beyond basic care, your press brake manufacturer may offer upgrades and retrofit packages. These retrofit programs help optimize the machine’s performance in lieu of purchasing a brand-new machine. Typically, these upgrades are about one-third the price of a new machine, depending on the size.

OEM-certified service technicians may even be able to complete most of the upgrades on-site, keeping downtime to a minimum.

Gain an Advantage With Hydraulic Press Brakes

Each component of a hydraulic press brake works together to deliver high-quality performance. Regular maintenance of the press brake is the most cost-effective method to keep the machine operating at its best and reduce unexpected downtime.

Pacific Press is an expert in hydraulic press brakes with our longstanding history in the industry. Our hydraulic press brakes are some of the most durable machines available. We particularly take pride in our valves, which have been trusted in the industry longer than most and have proven their reliability over time. Learn more about our large press brakes and reach out with any further questions.